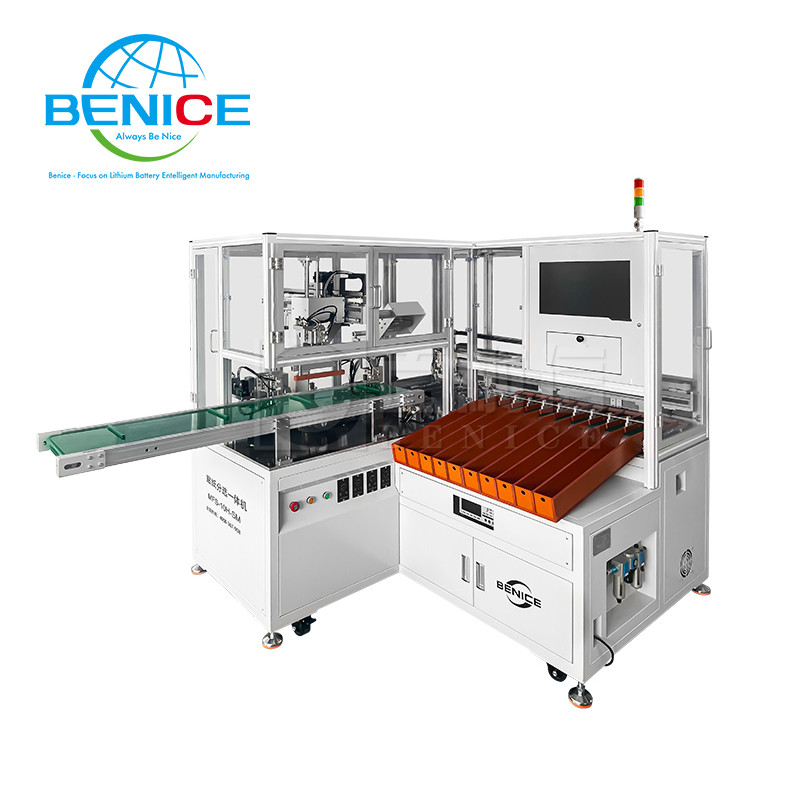

Best quality Automatic Sorting System – Sorter MFS-10H-SM – Benice

Best quality Automatic Sorting System – Sorter MFS-10H-SM – Benice Detail:

Product Features

Adjust the interval between the probe of the lithium battery sorter and the tested battery. Let the xenon lamp of the sorter flash for 5-10 times, calibrate the sorter with standard chips, and then test and sort the battery chips. Before testing and sorting the battery chips, it is necessary to calibrate the test bench with standard battery chips.

After the test and sorting, clean up the solar cells, prevent the mixing of solar cells with different power, and divide them by 0.1W. During the test, it is necessary for operators to wear finger covers, and it is forbidden to carry out test sorting without finger covers.When handling and placing the battery, try to be light and try not to impact the nickel sheet of the battery.Battery sorting is the first and one of the important processes in the production of battery components. Now let’s introduce the intention and precautions of battery slice electrical performance sorting.

Purpose

Try to keep the power of each battery in each component within the planning range.

Precautions for lithium battery active sorter:

Do not touch the battery with bare hands;

During operation, the battery should be handled with care;

Before the startup test, the standard battery should be calibrated. When testing different standard batteries, the standard batteries with different specifications should be calibrated;

Check whether the equipment is in good condition;

During the test, eyes should not look directly at the light source to prevent eye injury;

Before unpacking the battery, check whether the outer package is damaged. If yes, take photos and report it. If there is no damage, unpack and check the battery;

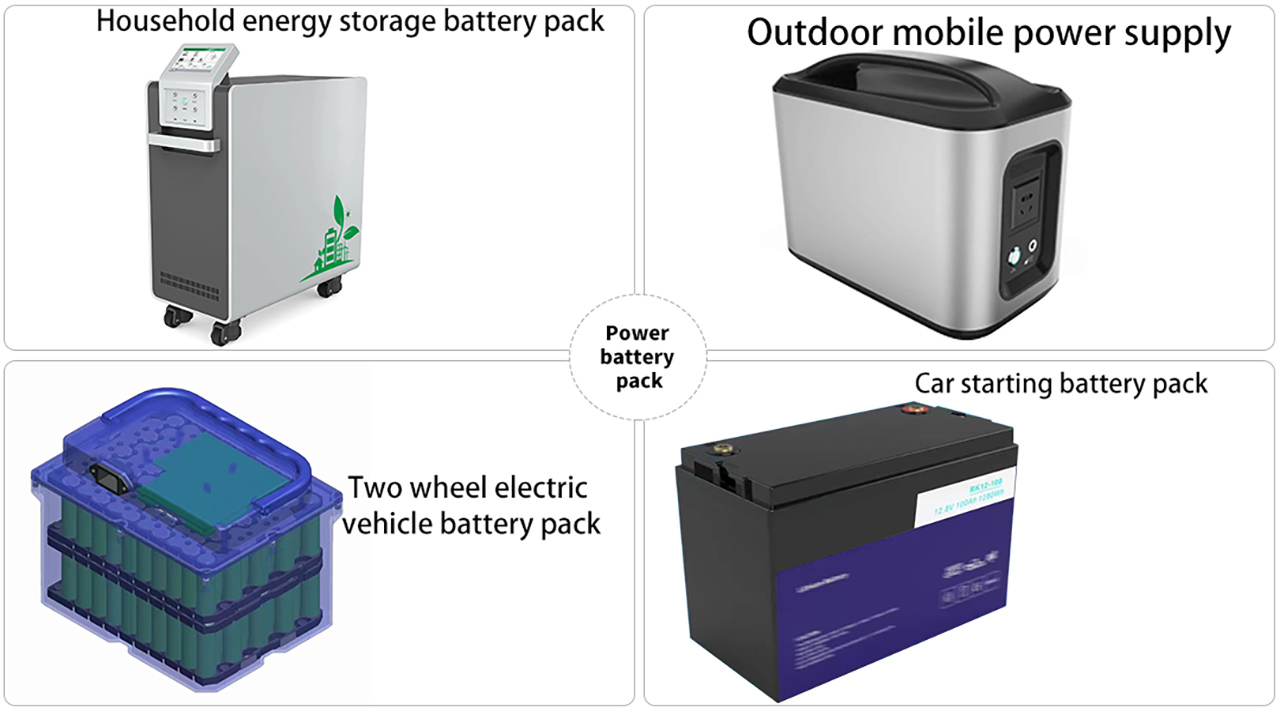

Application Areas

Because of the randomness of the battery production conditions, the battery performance produced is different, so in order to effectively combine the batteries with the same performance or nearby, they should be classified according to their performance parameters.Battery test sorting is to classify the battery by measuring the size of its output parameters (current and voltage).Battery test and sorting is to classify the output parameters (current and voltage) of the battery through testing, so as to improve the utilization rate of the battery and make qualified battery components.

Video

Product detail pictures:

Related Product Guide:

We thinks what customers think, the urgency of urgency to act in the interests of a customer position of principle, allowing for better quality, lower processing costs, prices are more reasonable, won the new and old customers the support and affirmation for Best quality Automatic Sorting System – Sorter MFS-10H-SM – Benice , The product will supply to all over the world, such as: Hongkong, Manchester, Vietnam, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.