High Performance Spotwelder Diy - Automatic laser welding machine – Benice

High Performance Spotwelder Diy - Automatic laser welding machine – Benice Detail:

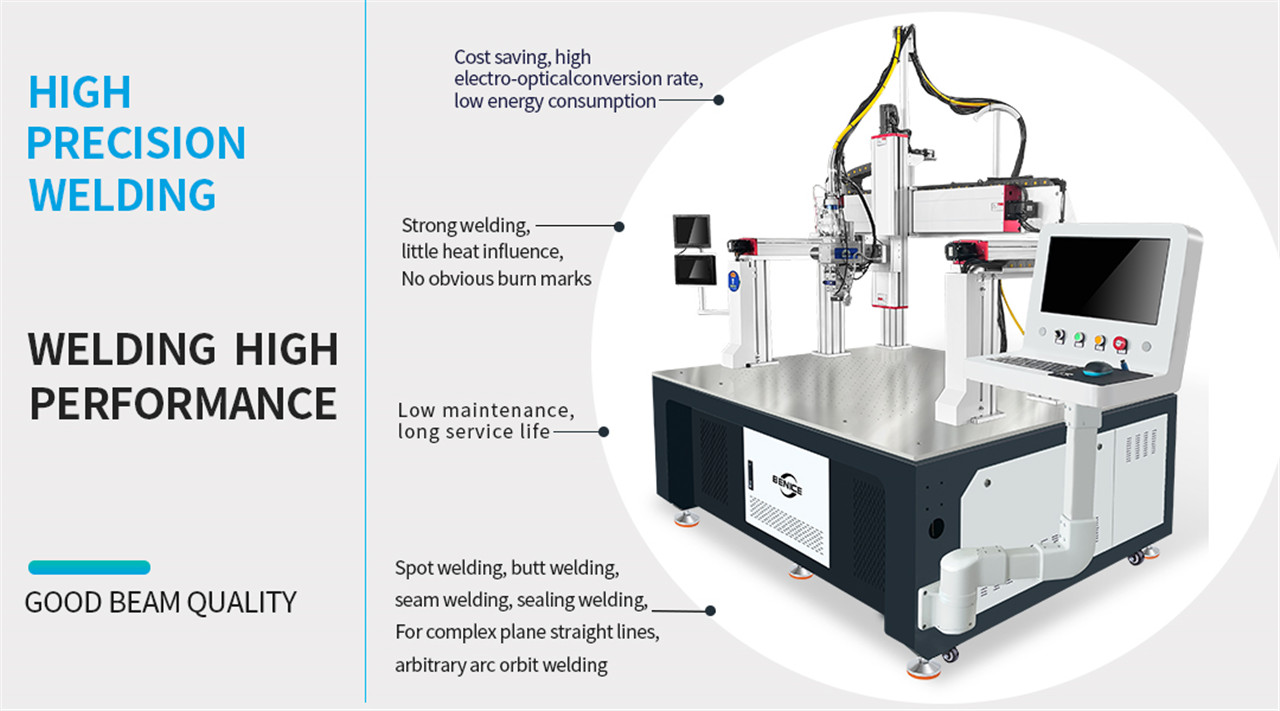

Product Features

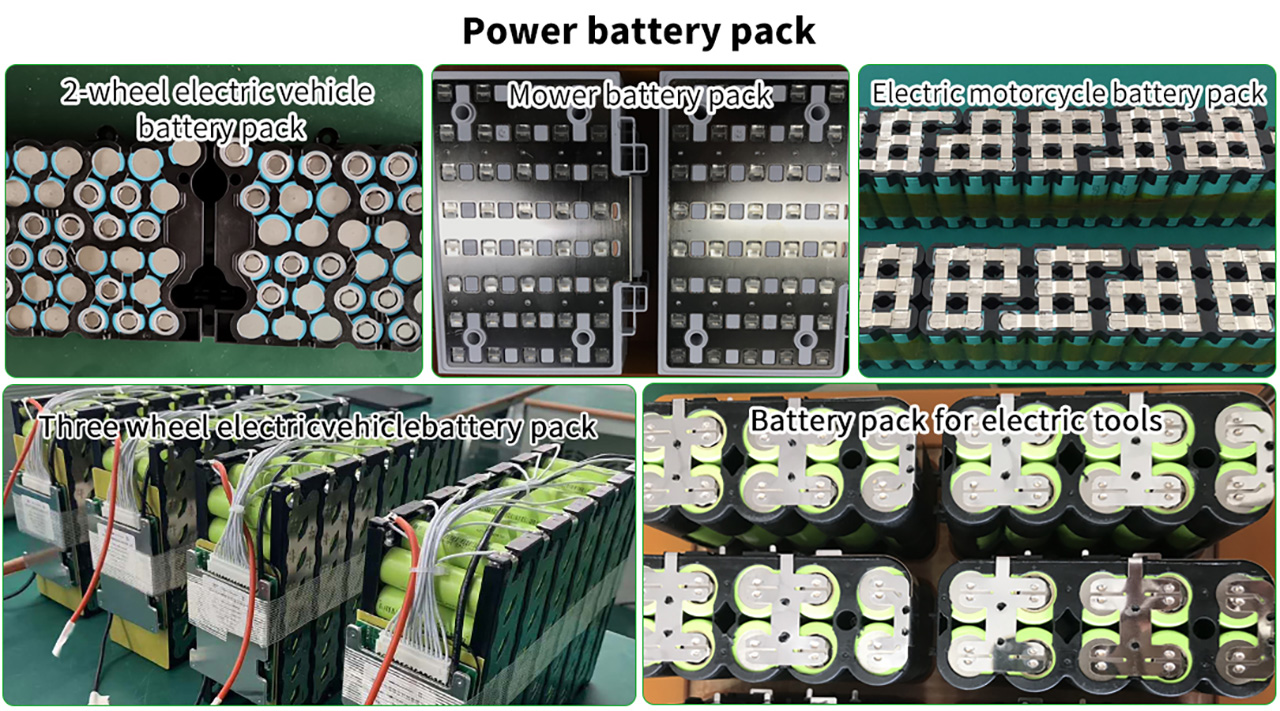

Laser welding can be applied to the welding of various metals, alloys, steel and other alloy materials, as well as the welding of copper brass, copper titanium, nickel copper, copper titanium and other dissimilar metals.Automobile engine cylinder gasket; Sealing welding of hydraulic tappet; Sealing welding of filter; Spark plug welding; Valve push rod welding; Sealing welding of anti-collision airbag electric detonator; Heat treatment of crankshaft or cylinder liner; Shell sealing welding of mobile phone battery and power battery; Solid state relay seal welding; Connector data line welding; Hardware tools, accessories, tableware, lighting fixtures;

Precautions for laser welding machine precautions for laser welding machine

In the process of operating the laser welder, in case of emergency (water leakage, abnormal sound of the laser, etc.), immediately press the emergency stop and quickly cut off the power supply.

The external circulating water switch of laser welding must be turned on before operation.

Since the laser system adopts water cooling mode and the laser power supply adopts air cooling mode, if the cooling system fails, it is strictly prohibited to start up and work.

It is not allowed to dismantle any parts in the machine at will, and it is not allowed to weld when the safety door of the machine is opened. It is strictly forbidden to look directly at the laser or reflect the laser with your eyes, and face the laser welding joint with your eyes when the laser is working, so as to avoid eye injury.

Inflammable and explosive materials shall not be placed on the laser light path or where the laser beam can be irradiated, so as to avoid fire and explosion.

When the machine is working, the circuit is in the state of high voltage and strong current. It is strictly forbidden to touch the circuit components in the machine during operation.

Untrained personnel are forbidden to operate this machine.

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for High Performance Spotwelder Diy - Automatic laser welding machine – Benice , The product will supply to all over the world, such as: Malawi, Guatemala, Kazakhstan, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.