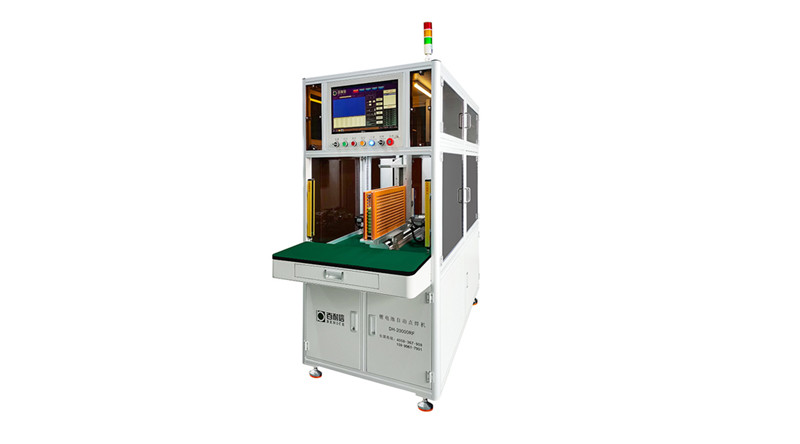

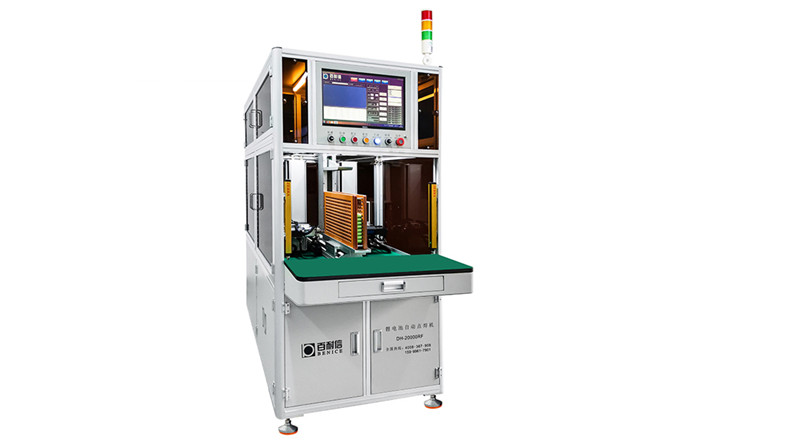

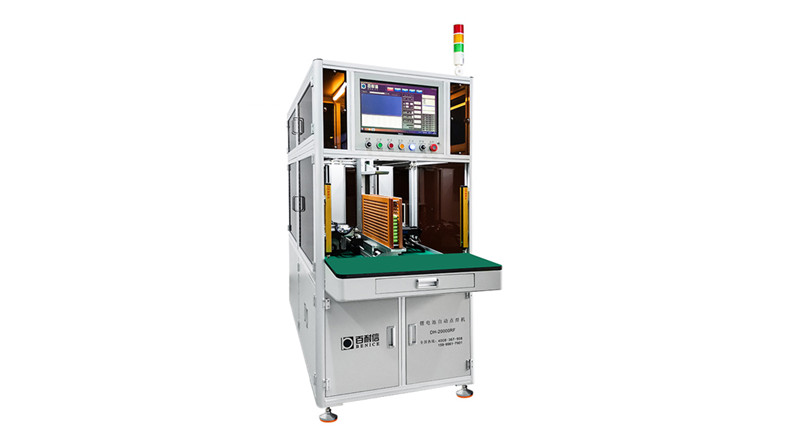

High Quality Spot Welding Machine - Lithium battery welder 20000RF – Benice

High Quality Spot Welding Machine - Lithium battery welder 20000RF – Benice Detail:

Product Features

With the social development and progress of our country, our demand for electronic products is more and more. Of course, the requirements for electronic products are also higher and higher.Automatic spot welding machine is also one of the electronic equipment we often use.Now people have more and more requirements for electronic products, and many young people return to their hometown to develop their own electronic business.

As a result, enterprises are facing more and more production costs and recruitment difficulties, and the production quality cannot be guaranteed, especially for electronic weldments.For example, manual welding of electronic products: the “consistency” of welding products cannot be guaranteed, which is prone to poor welding, high defect rate and low production efficiency. These factors have directly damaged many small and medium-sized enterprises.Now let Benice Technology Co., Ltd. introduce you to the safe operation specifications of automatic spot welding machine:

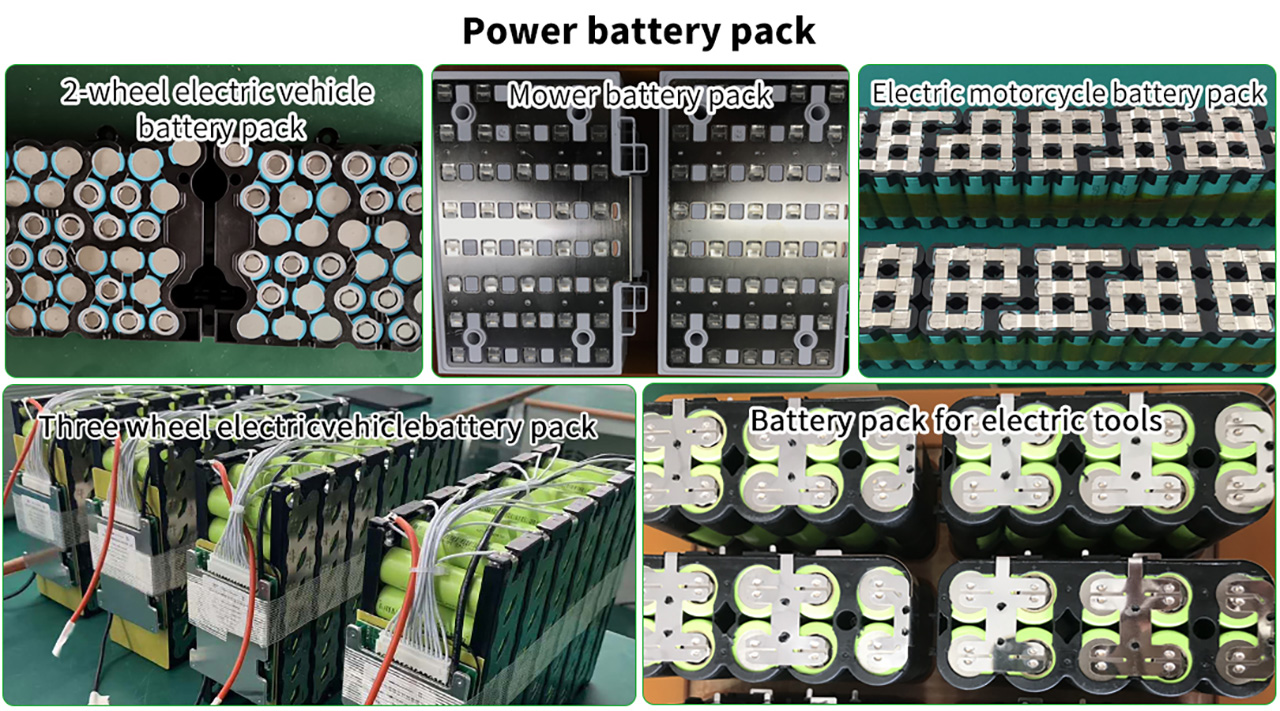

Application Areas

Oil stains and dirt must be removed before work, otherwise the service life of the electrode will be seriously reduced and the welding quality will be affected.

After the automatic spot welding machine is powered on, check the electrical equipment, operating mechanism, cooling system, air circuit system and body shell for leakage.Spot welder manufacturer

Before starting the automatic spot welding machine, first turn on the change-over switch of the control line and the small switch of the welding current, insert the knife switch position of the stage adjustment switch, turn on the water source, air source and the adjustment buttons on the control box, and then turn on the power supply to work.

The electrode contact shall be kept clean and bright, and can be polished with a fine file or emery cloth if necessary.

The bearing hinge of the automatic spot welding machine and the piston and liner ring of the cylinder should be lubricated regularly.

When the automatic spot welding machine is working, the air circuit system and water cooling system should be unblocked.The gas must be kept dry and should not contain moisture.The drainage temperature should not exceed 40 ℃, and the drainage flow can be adjusted according to seasons (smaller in winter and larger in summer).

After-sale service

When the automatic spot welding machine stops working under the temperature of 0 ℃, compressed air must be used to blow out the water stored in the cooling system to prevent the pipeline from cracking or blocking.

The working stroke of the upper electrode is achieved by adjusting the two nuts under the cylinder block. After adjustment, it must be tightened.

The electrode pressure can be adjusted by rotating the handle of the pressure reducing valve according to the requirements of the welding specification.

Avoid damage to the pilot tube and selenium rectifier, and it is strictly prohibited to increase the fuse in the pilot circuit.

When the load is too small so that the arc in the pilot tube cannot occur, it is strictly forbidden to close the pilot circuit of the control box, because at this time, the pilot circuit cannot be shunted by the arc, so that there is a large current passing through the pilot circuit during the closing period, which is easy to damage the pilot tube and selenium rectifier.

The circuit device of the control box is complex, so attention should be paid to protect the circuit facilities from being damaged by touch.When the temperature is low in winter, the thyristor and pilot tube are not easy to ignite.The indoor temperature should not be lower than 15 ℃.

After the automatic spot welding machine stops working, sundries and welding slag splashes must be removed.

When the automatic spot welding machine stops working, the power supply and air source should be cut off first, and then the water source should be turned off.Automatic spot welder

If the automatic spot welding machine is out of service for a long time, the moving parts that are not painted must be coated with antirust grease to prevent parts from rusting.

If the control box is out of service for a long time, in order to prevent moisture immersion, it should be powered on and heated for 30 minutes every month. If the thyristor is replaced, it should also be preheated for 30 minutes.

Video

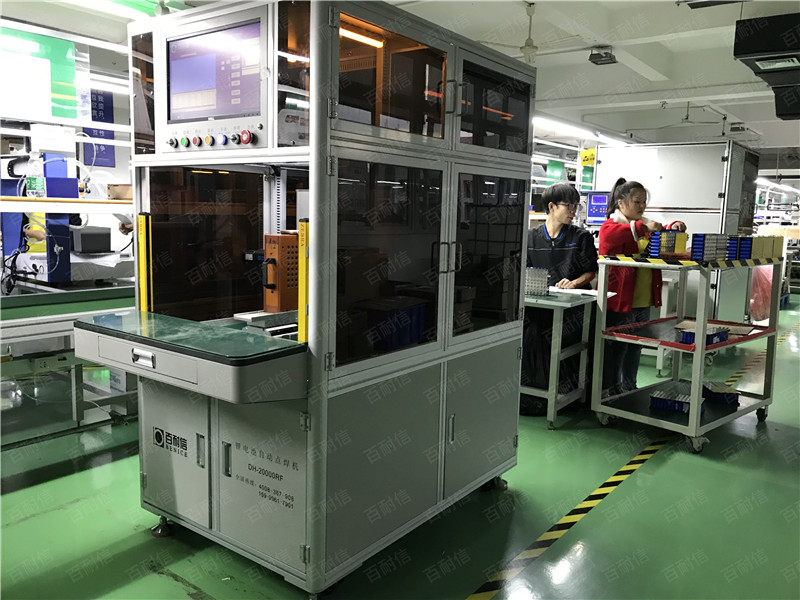

Product detail pictures:

Related Product Guide:

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for High Quality Spot Welding Machine - Lithium battery welder 20000RF – Benice , The product will supply to all over the world, such as: Auckland, Jamaica, Ecuador, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.