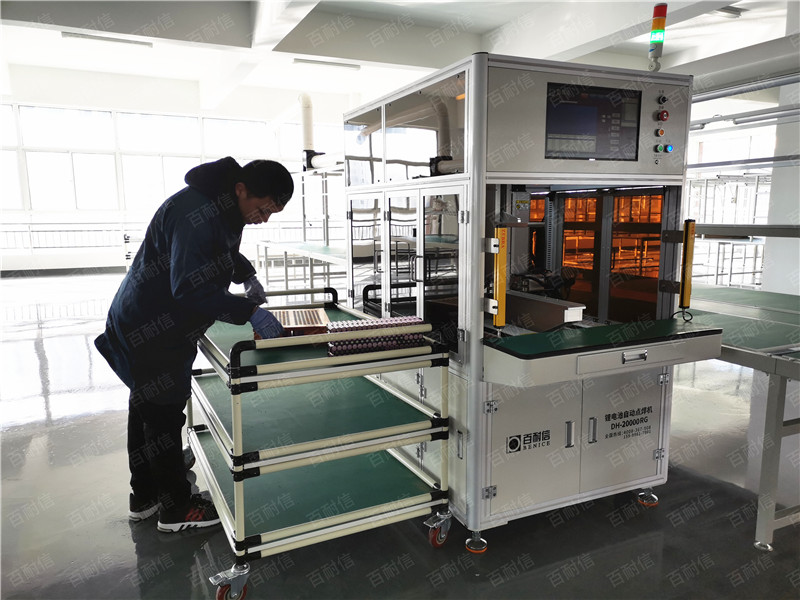

Quality Inspection for Lithium Ion Battery Spot Welder - Lithium battery welder 20000RG – Benice

Quality Inspection for Lithium Ion Battery Spot Welder - Lithium battery welder 20000RG – Benice Detail:

Product Features

The number of stages of the current regulating switch can be selected according to the thickness and material of the weldment. After power on, the power indicator light should be on, and the electrode pressure can be obtained by adjusting the spring pressure nut and changing its compression degree.

After the above adjustments are completed, the battery automatic spot welder can first connect the cooling water and then connect the power supply for welding.Welding process: place the weldment between the two electrodes, step on the foot pedal, and make the upper electrode contact with the weldment and pressurize. When the foot pedal is continuously pressed, the power contact switch is turned on, so the transformer starts to work, and the secondary circuit is energized to heat the weldment. When the pedal is released after welding for a certain time, the electrode rises, and the power supply is cut off first and then restored to the original state by the tension of the spring, and the single point welding process is over.

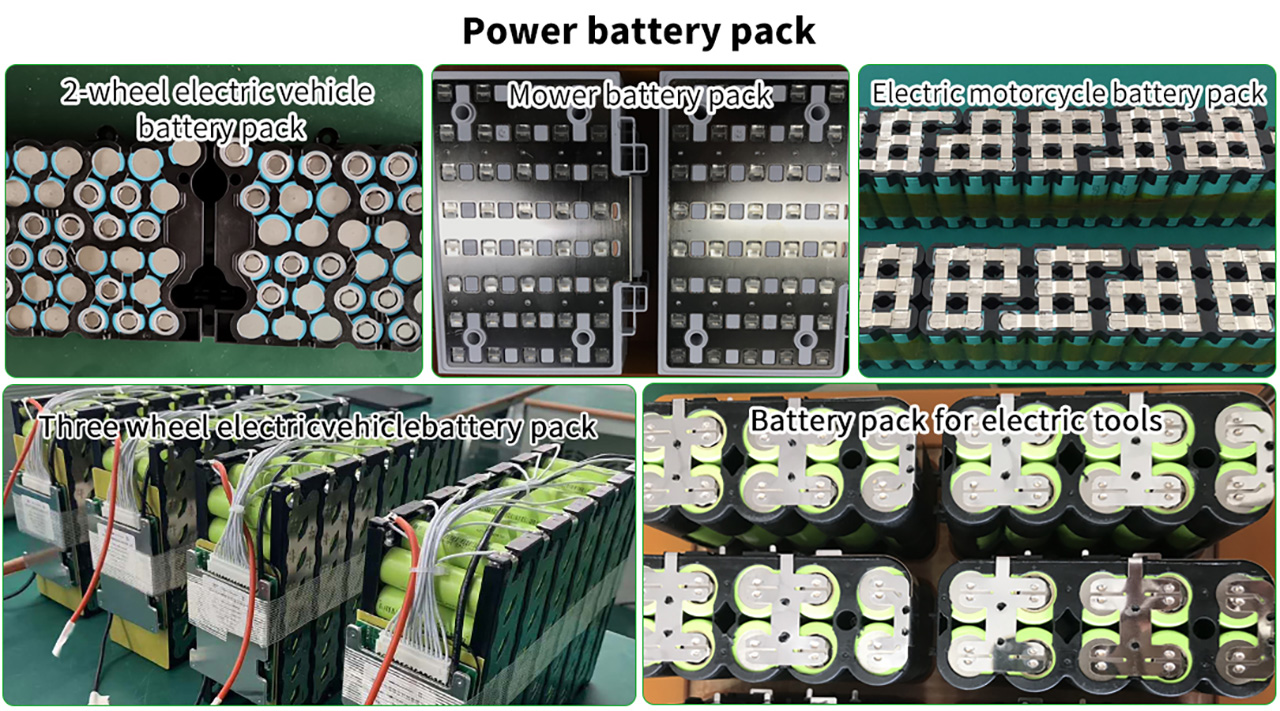

Application Areas

Instructions for battery automatic spot welder

The spot welding machine adopts the principle of double-sided double-point over-current welding. When working, two electrodes pressurize the workpiece so that the two layers of metal form a certain contact resistance under the pressure of two electrodes. When the welding current flows from one electrode to the other electrode, an instantaneous hot fusion is formed at the two contact resistance points, and the welding current instantly flows from the other electrode along the two workpieces to this electrode to form a circuit, without damaging the internal structure of the workpiece to be welded.

The process of spot welding is as follows: turn on cooling water, clean the surface of the weldment, send it between the upper and lower electrodes after accurate assembly, and apply pressure to make it contact well. Electrify the contact surface of the two workpieces to heat, local melting, forming a nugget; Maintain pressure after power failure, so that the nugget cools and solidifies under pressure to form solder joints.Remove the pressure and take out the workpiece. Welding parameters such as welding current, electrode pressure, power on time and electrode working surface size have a significant impact on welding quality.

The battery automatic spot welding machine uses the high-temperature arc generated by the positive and negative poles in the instant short circuit to melt the solder and the welded material on the electrode, so as to achieve the purpose of combining them. The structure of the welding machine is very simple. To put it bluntly, it is a high-power transformer, which changes 220V AC into a low-voltage, high current power supply, which can be DC or AC.The transformer of spot welding machine has its own characteristics, that is, it has the characteristics of sharp voltage drop.

Video

Product detail pictures:

Related Product Guide:

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Quality Inspection for Lithium Ion Battery Spot Welder - Lithium battery welder 20000RG – Benice , The product will supply to all over the world, such as: kazan, Orlando, Azerbaijan, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.