Sorter MFS-10G-SM

Product Features

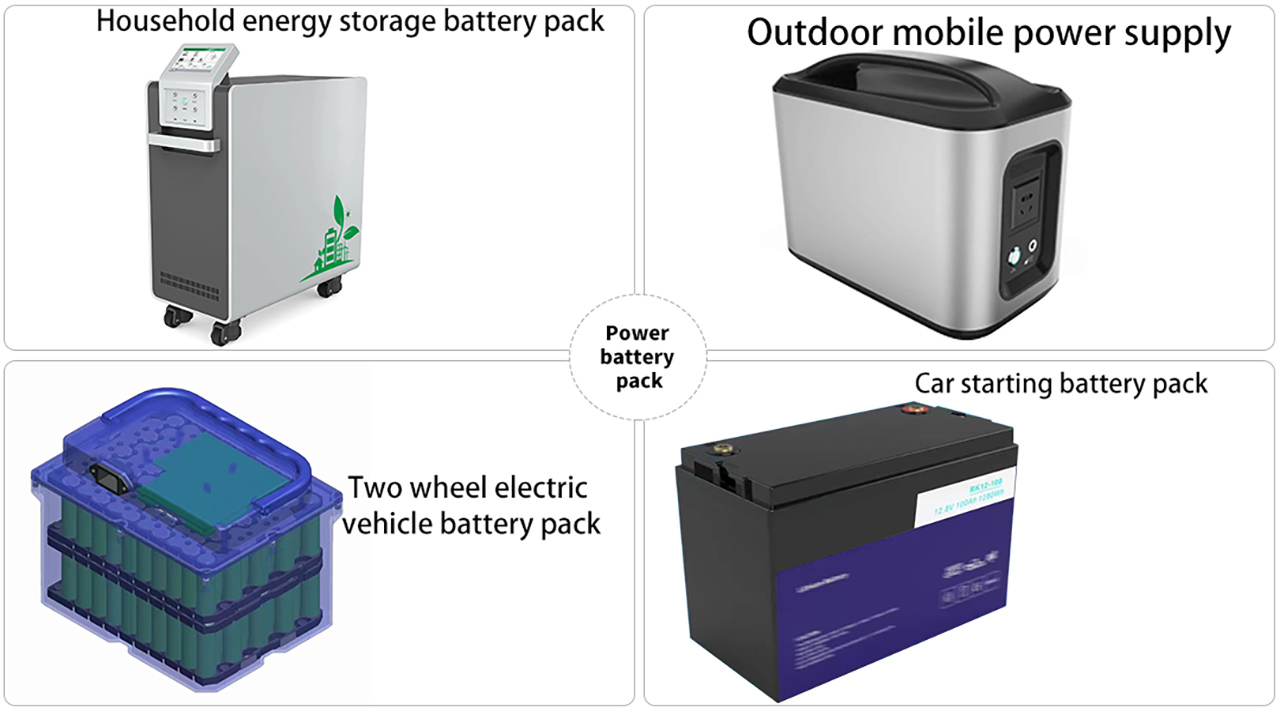

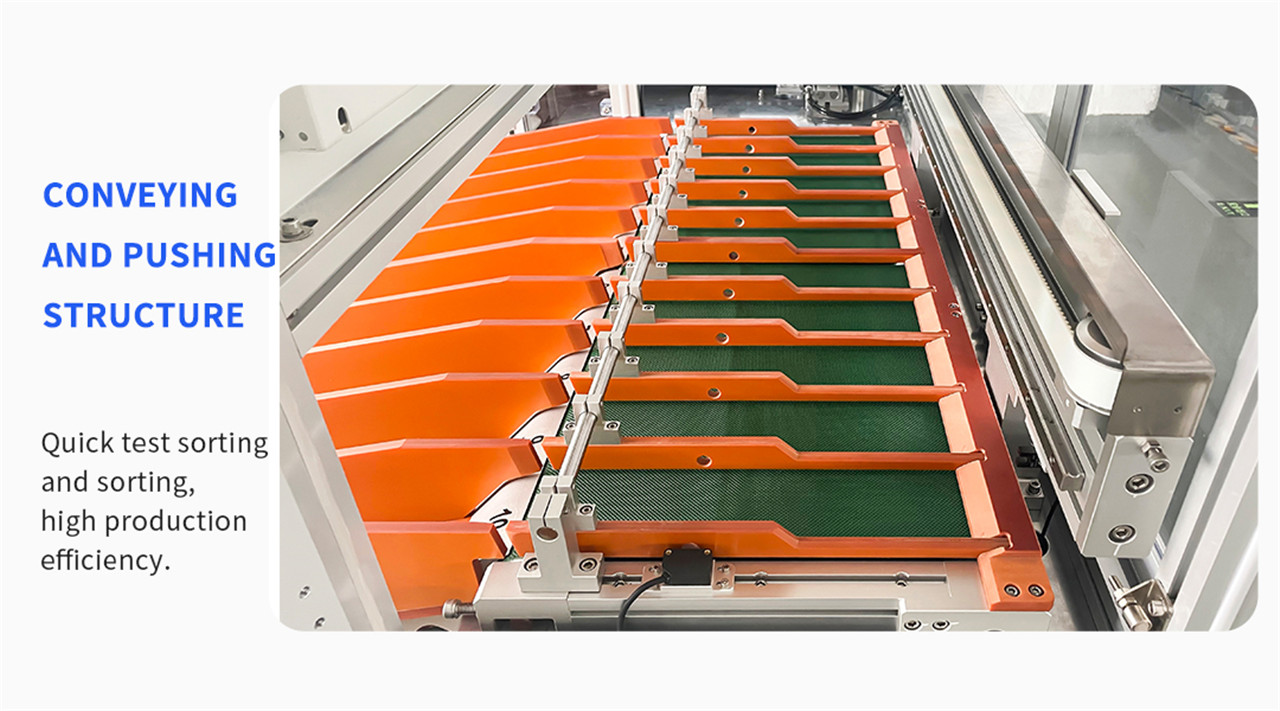

The 18650 lithium battery sorting machine adopts multiple take and place structures of servo manipulator, so that the time of material distribution of each battery is less than 1 second.

The sorting box of the sorter adopts a 5-20 gear structure, which has the function of full material alarm. The door at the end of the box is opened for convenient and rapid feeding.

The internal resistance voltage detection results of the battery sorter are analyzed by the computer to generate classification data and generate curves and bar charts together, which facilitates the visual accounting and flash of batch production quality.The detection system has the function of database, which can query, calculate and export historical detection data.

How to use lithium battery automatic sorting machine correctly

Turn on the main power supply and switch on the load.

Turn on the key switch on the main control equipment.

Press and hold the switch on the main control equipment to change the operation of the battery sorter from pause to work.

Turn on the computer and run the simulation test program.

After-sale service

Adjust the distance between the probe of the lithium battery sorter and the tested battery. Let the xenon lamp of the sorter flash for 5-10 times, calibrate the sorter with standard pieces, and then check and sort the battery pieces. Before checking and sorting the battery pieces, calibrate the test bench with standard battery pieces.After the inspection and sorting, the solar cells should be sorted to prevent the mixing of solar cells with different power, and graded at 0.1W.

During the inspection process, the operator must wear finger covers to prevent inspection and sorting without finger covers. When handling and placing the battery, try to be light, and try not to rub the battery, resulting in damage to the antireflection film.Cell sorting is the first and one of the important processes in the production of battery components. Now let's introduce the purpose and purpose of cell electrical performance sorting.